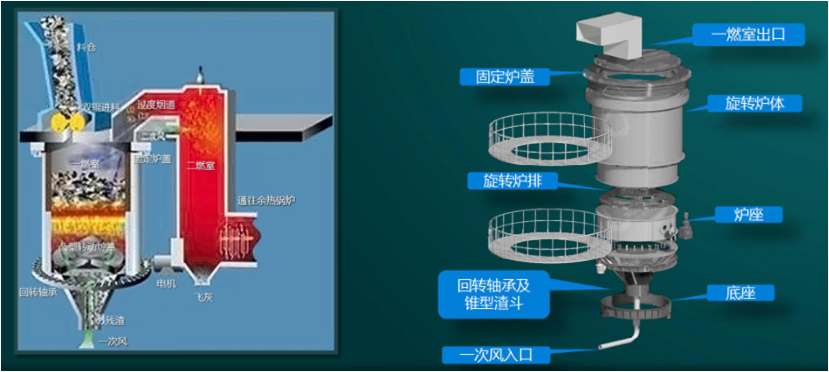

On the municipal solid waste treatment equipment, where we mainly introduce Huatai company manufacturing vertical rotary pyrolysis gasifier. Huatai independent research and development of vertical rotary pyrolysis gasifier using the world's most advanced vertical rotary pyrolysis gasification technology, the use of pyrolysis gasification principle of solid waste treatment to ensure the stability of the combustion conditions And high efficiency, without any auxiliary fuel conditions, with "high thermal efficiency, a burning room temperature is high, the rate of low heat burning, the small amount of fly ash emissions, dioxin emission concentration is low," and other technical advantages, and " Furnace structure is simple and compact, start and stop the furnace convenient operation, easy maintenance, low energy consumption, the furnace light weight, small footprint, low construction costs "and other economic advantages, has formed a single furnace processing capacity of 5 ~ 150t / d Of the multi-series furnace, is the most development potential at home and abroad a new generation of small and medium-sized waste disposal equipment.

Huatai vertical rotary pyrolysis gasifier and the traditional grate furnace technology, fluidized bed technology for direct combustion of different garbage, we use vertical rotary pyrolysis gasification technology using the principle of pyrolysis gasification technology using two-stage treatment process , The first garbage in a combustion chamber for pyrolysis gasification, and then gasification after the small molecules combustible gases (such as hydrogen, carbon monoxide, methane and other gaseous hydrocarbons) in the secondary combustion chamber for oxygen combustion, pyrolysis The resulting carbon black, tar and other combustible materials in a combustion chamber combustion of oxygen, the temperature of up to 1000 degrees, for garbage pyrolysis, gasification to provide sufficient heat, therefore, vertical rotary pyrolysis gasification technology equipment in There is no need to provide auxiliary fuel during the waste disposal process. The vertical distribution of a combustion chamber temperature field is also conducive to the waste pyrolysis, gasification, reduce the burning rate of waste burning.

Huatai vertical rotary pyrolysis gasifier uses vertical rotation design, the furnace and the lid of the relative rotation skillfully solve the technical problems of uneven cloth, furnace and grate relative rotation to solve the technical problems of continuous slagging , But also played a role in stirring the garbage, more conducive to the pyrolysis of gasification. Since the secondary combustion chamber burns small combustible gases, the pollutants such as: SOx (acid gas), NOx (nitrogen oxides), dioxin, heavy metals are very small, especially the amount of fly ash is less than the amount of waste , Which is much lower than the furnace technology and the amount of fly ash produced by the fluidized bed technology, which greatly reduces the secondary pollution caused by waste disposal, and also reduces the cost of tail gas treatment.