PLC Control System Using The Entire Computer Control, Electrical Components Using Well-Known Brand Products, System Stability, Reliability And Strong;

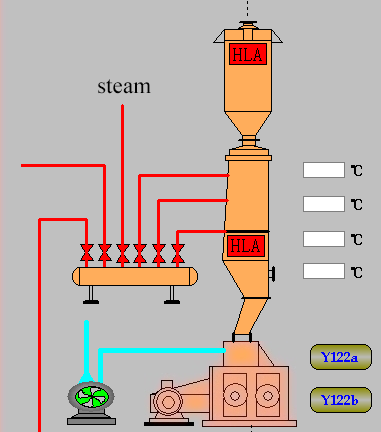

The System Uses The Entire Computer Simon PLC Integrated Control System: For The Corn Tablet Compression Humidification, The Heating, The Tablet System, In The System Carries On The Electrical Machinery Control, The Valve Control, The Temperature Display, The High And Low Level Display By The PLC, The Electrical Machinery Breakdown And The High And Low Level Alarm.

System Advantages:

Save Labor, The Minimum Only One Person On Duty. Highly Automated, Independent Of Labor.

The Control Interface Is Clear:

Equipment Operation And Fault Status Display To The Host Computer, To Facilitate The Operator To Monitor The Field Equipment, Material Operation Is Normal. Through The PLC On The Equipment To Monitor The Temperature Of The Material, High And Low Temperature Alarm, Control Of The Material Temperature On The Corn Humidification, Heating To Improve The Best Effect Of Corn Embryo Molding;

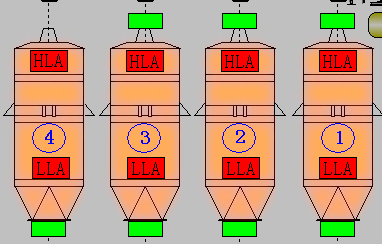

Raw Material Infiltration Material Warehouse Level Valve, The Use Of Automatic Control, Easy To Accurately Control The Production Line Production:

Equipment Raw Materials Feed Corn Kernels, Through The Pre-Cleaning Sieve, Stone Machine, Brake Kelon And Other Cleaning Equipment To Clean Up The Corn To 1,2,3,4 Equal Number Of Silos, From The High-Material Level Warehouse To Control The Feed Valve Of The Switch, The Material From The Run Material Low-Bit Material To Open Control Of The Opening Of The Material Out Of The Silo Valve Switch, And Set At The High-End Material Level Sound And Light Alarm;

Temperature And Material Level Control, Temperature PID Control, Reduce Labor Intensity, Improve The Stability Of Process Parameters:

The Material Is Transported To The Feed Bin Of The Conditioning Tower, And The High And Low Material Level Of The Quenched And Tempered Tower Is Set. The Temperature Detection Is Controlled By The High And Low Material Level Of The Quenching Tower And The Process Temperature Value Of The Quenching And Tempering Tower. Rolling Mill Fabric Motor Feeding Frequency, And In The High, Low Material Level, High And Low Temperature Sound And Light Alarm Set;

Temperature Setting High, Low Temperature Alarm, Continuous And Stable Control, According To The Quality Of Raw Materials And Product Requirements Set To Adjust:

Material Temperature Are Set To High And Low Temperature Alarm, Monitoring The Material In The Tempering Tower Temperature, And Real-Time Data Show The Temperature Curve;

When The Process Temperature Is Higher Than The Set Temperature Alarm, PLC Will Send Alarm Signal, Sound And Light Alarm;

When The Process Temperature Is Lower Than The Set Temperature Alarm, PLC Will Issue An Alarm Signal, Sound And Light Alarm;

Temperature Curve For The Display Of Material Temperature Record And Print Temperature Report, Real-Time Monitoring Of The Temperature Of The Material Condition