- Dehulling

- Shelling

- Pressing

-

Walnut Dehulling

The harvested walnuts are put into the walnut hulling machine to remove the walnut hulls.

This walnut processing machine integrates the functions of hulling and washing. It adopts a high-speed rotating hob to cut off the hulls. The uncut hulls are removed by the steel brush in the walnut machine. The hulled walnuts are washed to remove the mucus on the surface.

GET A QUOTE -

Walnut Shelling

The hulled walnuts are first graded by the walnut grading machine and then cracked by the walnut cracking machine. The walnut cracking machine adopts rollers to crack the walnuts. The mixture of walnut shells and kernels is separated by the walnut shell and kernel separator.

GET A QUOTE -

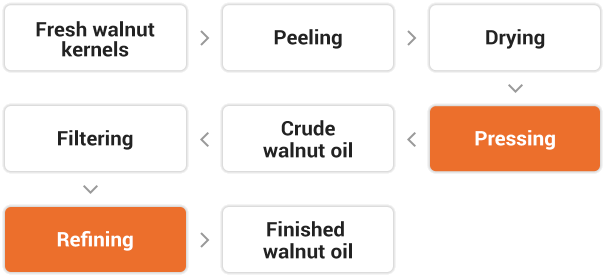

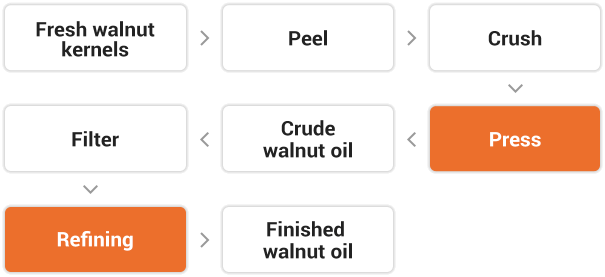

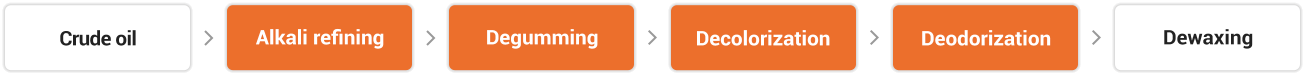

Walnut Pressing

Walnut oil production line equipment can use cold pressing, hot pressing, and double pressing methods to obtain walnut oil. Maximize walnut oil production and ensure oil quality.

GET A QUOTE