Cottonseed Oil Production Line

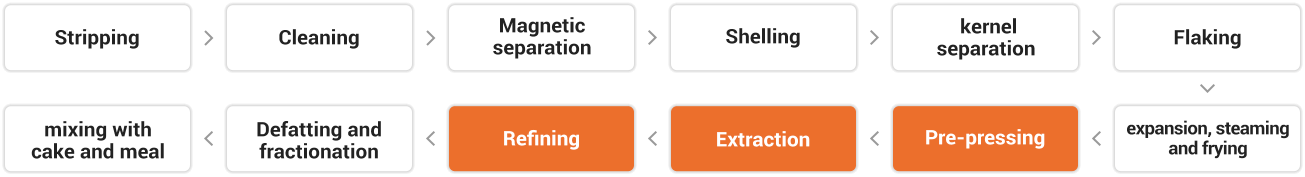

Cottonseed oil production process usually uses Cottonseed Oil pre-pressing Machine, Cottonseed Oil Extraction Machine, and Cottonseed Oil Refining Machine. Cottonseeds can be once-pressed and then sent to the cottonseed oil refinery plant directly. For a capacity of more than 20 tons per day, usually, the solvent extraction method is usually adopted with cottonseed oil pre-press used to extract part of the oil. The machine has a large capacity and the cake has a low residual oil rate and is easy for solvent penetration. The pre-pressing and extraction method produces cottonseed oil and crude cottonseed oil refining. The pretreatment steps mainly include cleaning, shelling and crushing, steaming and frying, and pressing. Cottonseed oil refining can remove peptidic impurities, free fatty acids, pigments, odors, and other impurities in cottonseed oil, and improve the stability of cottonseed oil.