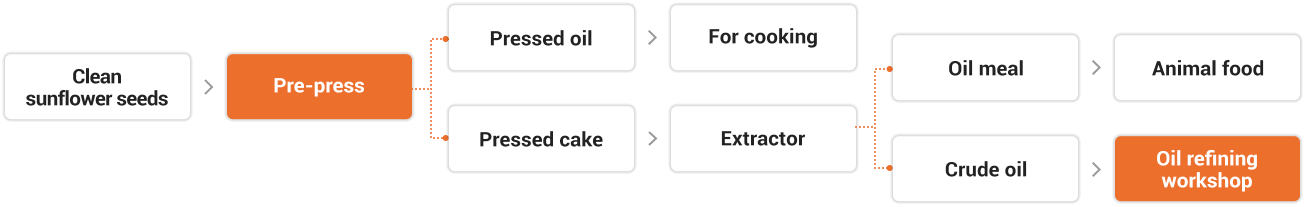

Sunflower Seed Oil Processing Steps

The processing characteristics of first-grade sunflower oil are:

First, sift the sunflower seeds and clean them to remove impurities, and then shelled and crushed the seeds. The embryo is peeled, steamed in a frying pan, the oil is pre-pressed from the deep-fried product, the remaining oil is extracted by solvent, and the crude oil is purified by precipitation and filtration.

Finally, the oil is dissolved, degummed, decolorized, deacidified and deodorized into finished oil. (Read more: Sunflower seed oil extraction method >>)

.jpg)