Complete set of oil solvent extraction solutions

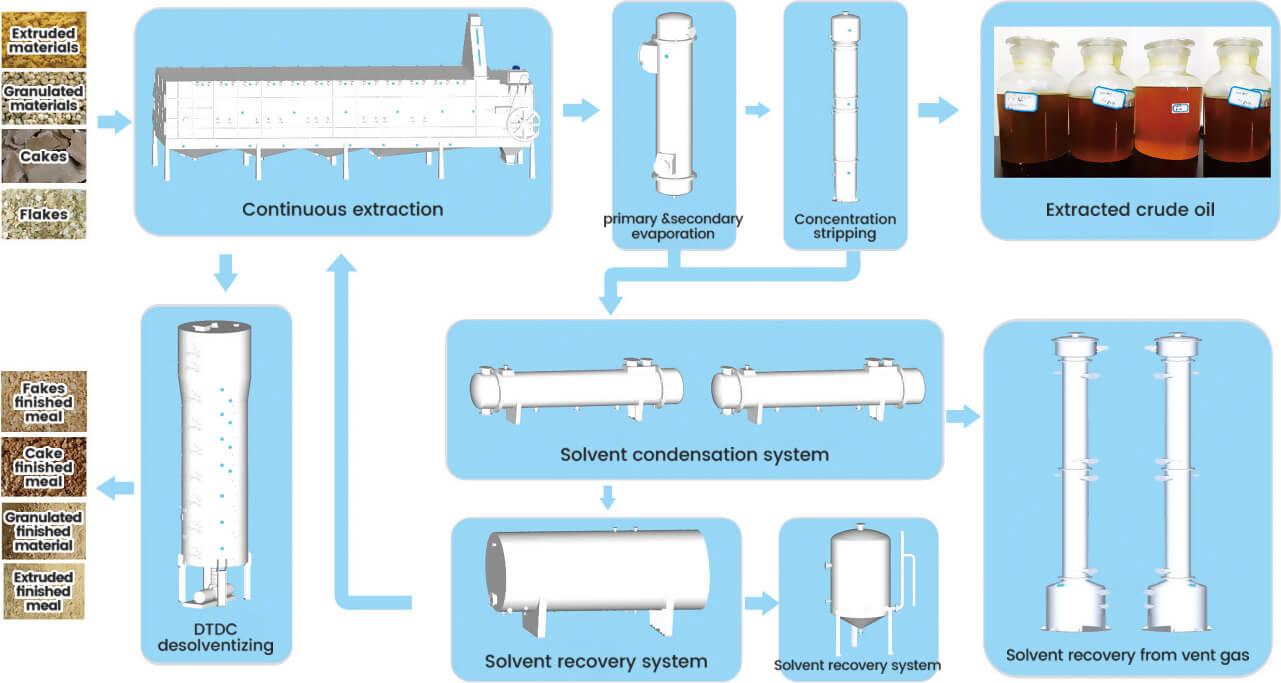

Extraction Process

The 2000T/D soybean solvent extraction project.

The 2000T/D soybean solvent extraction project

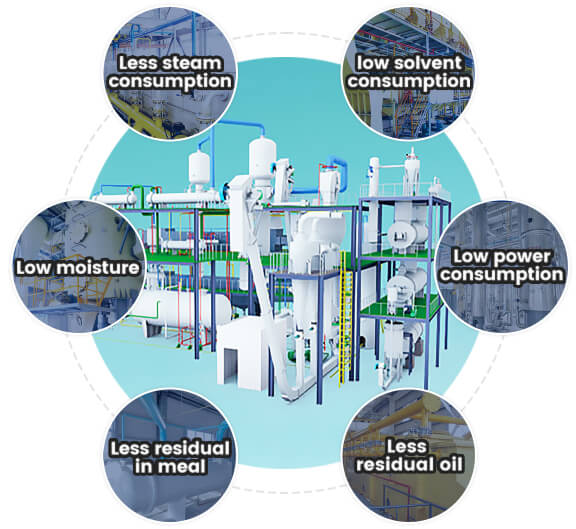

Technical Advantages

The technical advantages of Huatai complete set of solvent extraction project.

-

![]()

Comprehensive consideration of the utilization of steam exhaust water and the heat exchange of materials in the process, effectively reducing steam consumption.

-

![]()

The VRS layer is added by steaming and de-bonding, which can reduce the residual solvent in the meal and the solvent consumption.

-

![]()

Adopt a reasonable exhaust gas absorption system to effectively reduce the solvent content in the exhaust gas.

-

![]()

The equipment in the extraction workshop has strong adaptability and can meet the processing of different materials. The Automatic control system reduces the labor intensity of workers.

-

![]()

The evaporation system adopts a combination of steam and mechanical vacuum to reduce production costs and ensure the quality of crude oil.

-

![]()

Equipped with pumps and reducers of well-known brands, which can reduce the failure rate of workshop equipment.

Processing Output

The output of Huatai full automatic solvent extraction equipment.

- 30-5000T/D

- 30-1000T/D

- 30-5000T/D

- 30-1000T/D

- 30-5000T/D

-

30-500T/D

Tea seed solvent extraction project

- 30-5000T/D

-

30-500T/D

Sesame solvent extraction project

- 30-5000T/D

- 30-500T/D

-

30-5000T/D

Corn germ solvent extraction project

-

30-500T/D

Safflower seed solvent extraction project

-

30-5000T/D

Castor seed solvent extraction project

-

30-500T/D

Cyperus solvent extraction project

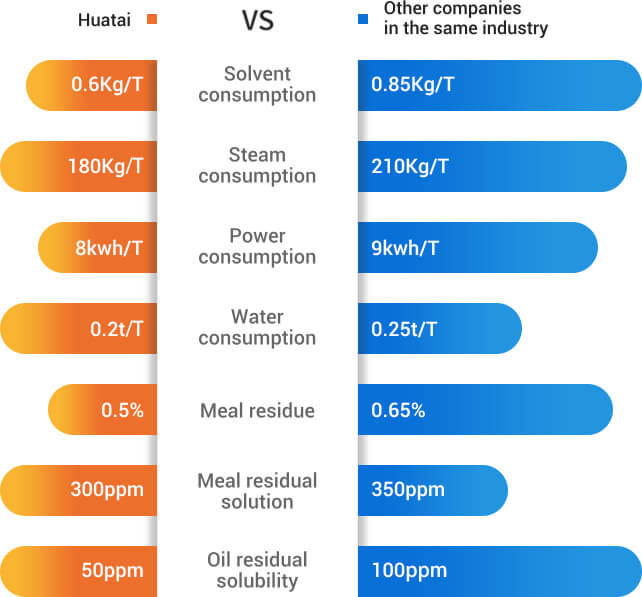

Parameter Comparison

Comparison of 2000 tons of soybean solvent extraction parameters in the same industry.

Indicator Advantages

The index advantages of the Huatai solvent extraction process.