Complete set of oil refining solutions

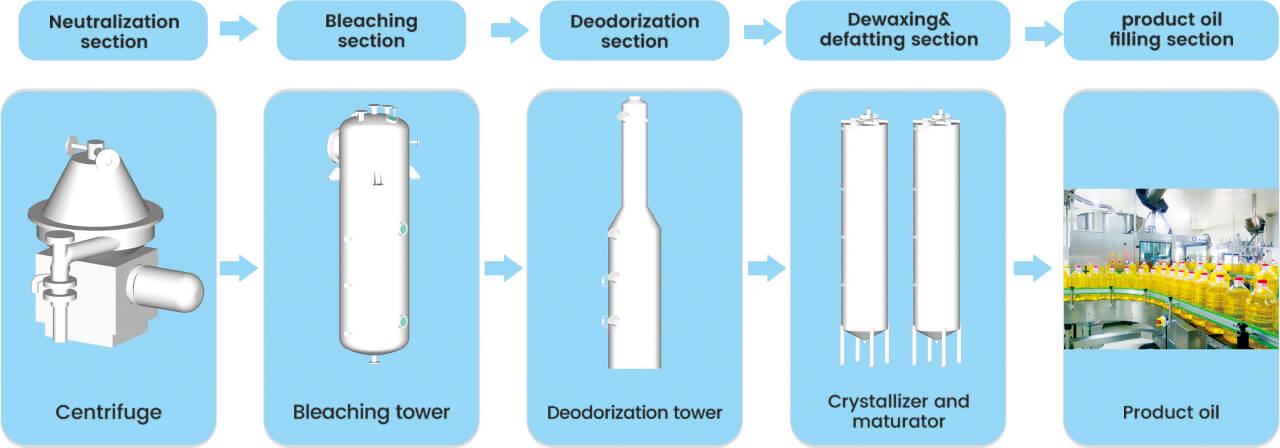

Refining Process

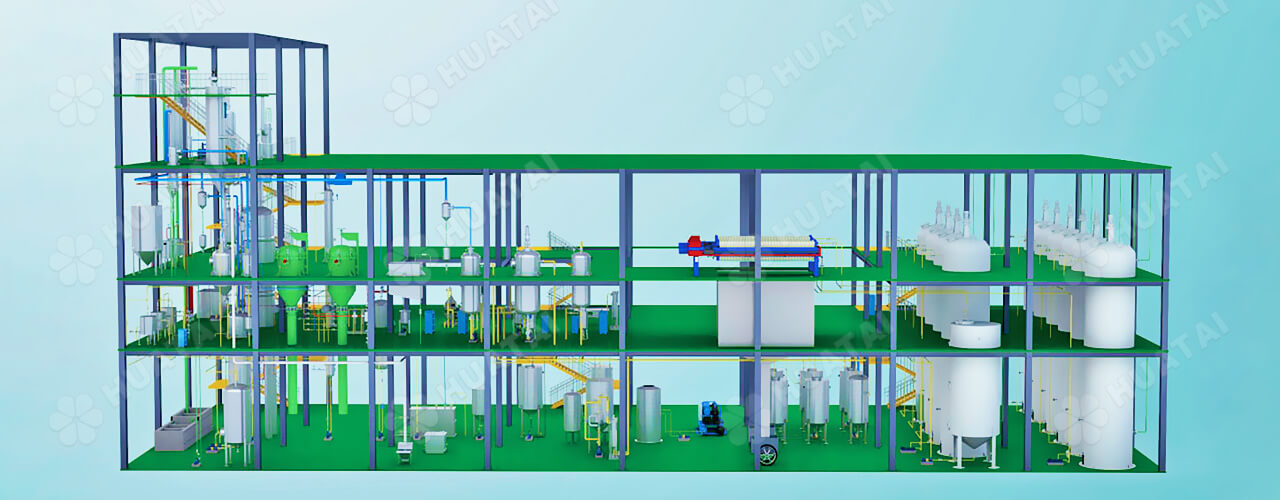

The 300T/D rice bran oil refining project.

300T/D rice bran oil refining project

Huatai's professional customized service provides customers with optimized oil refining solutions. providing professional refining solutions for different oil products and needs. Advanced process design, reasonable equipment structure design, refined equipment manufacturing, and highly automated technical support ensure that every drop of oil produced is safer. healthier. and more nutritious!

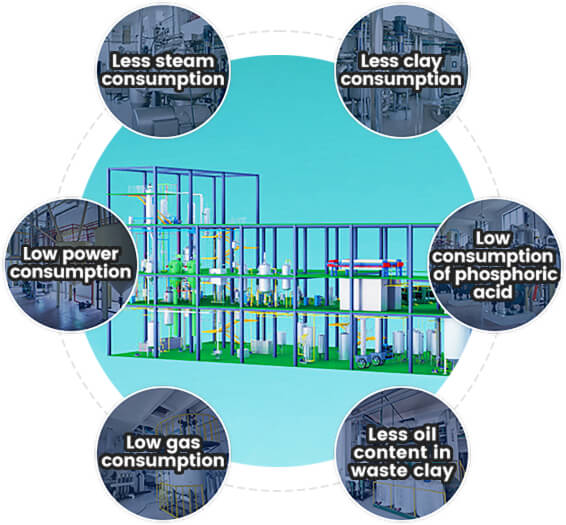

Technical Advantages

The technical advantages of Huatai complete set of refining project.

-

![]()

Huatai can provide advanced refining processes according to different oil products and needs, the refining process mainly includes enzymatic degumming, Anhydrous soap removal, Pre bleaching, fatty acid two-stage capture, etc.

-

![]()

When blowing cake with clay, a device for odor capture is designed to eliminate odor pollution in the decolorization process and meet the requirements of environmental protection.

-

![]()

The workshop has a high degree of automation, full computer display, and automatic control; the preheating and reuse technology is adopted to maximize waste heat in the production line and reduce steam consumption.

-

![]()

The vacuum system adopts a freezing or chilled water vacuum system, which greatly reduces the low steam consumption and wastewater discharge: It has the advantages of high product yield, excellent oil indicators, and low consumption.

Processing Output

The output of Huatai full automatic oil refinery.

- 30-1200T/D

- 30-1200T/D

- 30-1200T/D

- 30-500T/D

- 30-1200T/D

- 30-500T/D

- 30-1200T/D

-

30-300T/D

Tea seed oil refining project

- 30-1200T/D

-

30-300T/D

Sesame oil refining project

-

30-1200T/D

Corn germ oil refining project

- 30-300T/D

-

30-1200T/D

Castor seed oil refining project

-

30-300T/D

Safflower seed oil refining project

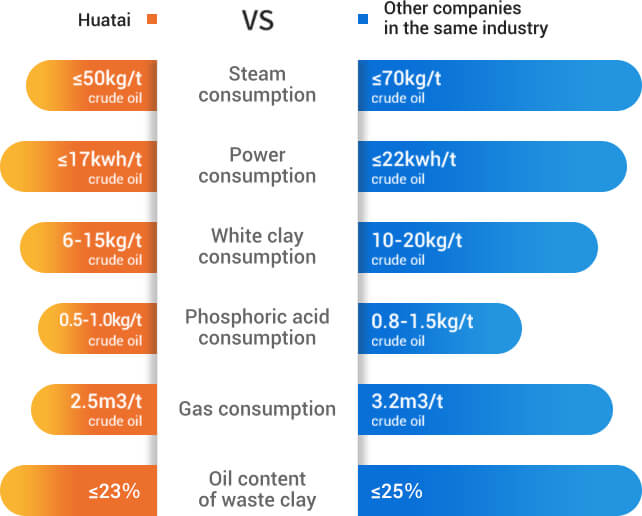

Parameter Comparison

Comparison of 300 tons soybean refining process parameters in the same industry.

Indicator Advantages

The index advantages of the Huatai refining process.