Overview

The degumming process in an oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extraction from oilseeds, crude oil mainly contains triglycerides and a few non-triglyceride.The non-triglyceride composition including phospholipids, proteins, phlegmatic, and sugar would react with triglycerides to form colloids, which are known as gum impurities.

Features

GET A QUOTEThe gum impurities not only affect the stability of the oil but also affect the process effect of oil refining and deep processing. For instance,non-degummed oil makes it easy to form an emulsified oil in the alkaline refining process, thus increasing the difficulty of operation, oil refining loss, and auxiliary material consumption.

In the decolorization process,non-degummed oil will increase the consumption of adsorbent and reduce discoloring effectiveness. Therefore, gum removal is necessary as the first step in the oil refinery process before oil deacidification, oil decolorization, and oil deodorization.

The specific methods of degumming include hydrated degumming, acid refining degumming, alkali refining method, adsorption method, electropolymerization, and thermal polymerization method.

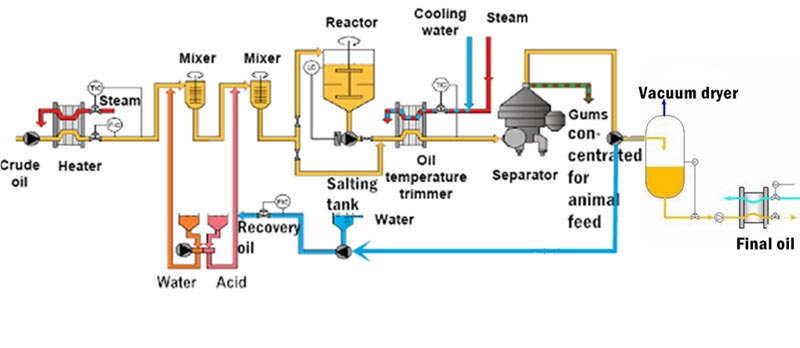

In the edible oil refining process, the most commonly used method is hydrated degumming, which can extract the hydratable phospholipids and some non-hydrate phospholipids, while the remaining non-hydrate phospholipids need to be removed by acid refining degumming.

The gum impurities such as phospholipids have the characteristic of hydrophilic. First of all, you can stir and add a certain amount of hot water or electrolyte aqueous solution like salt phosphoric acid to the hot crude oil. After a certain reaction period, the gum impurities would be condensed, subsided, and removed from the oil.

In the hydrated degumming process, the impurities are mainly phospholipid, as well as a few proteins, glyceryl diglycerides, and mucilage. What's more, the extracted gums could be processed into lecithin for food, animal feed, or for technical uses.

In an oil refining plant, the hydrated degumming machine can be operated together with an oil deacidification machine, decolorization machine, and deodorizing machine, and these machines are the composition of the oil purifying production line. The purifying line is classified into intermittent type, semi-continuous type, and fully continuous type.

The customer could choose the type according to their required production capacity: the factory with a production capacity of 1-10t per day is suitable for using intermittent type equipment,20-50t per day factory is suitable for using semi-continuous type equipment, producing more than 50t per day is suitable for using fully continuous type equipment. The most commonly used type is the intermittent hydrated degumming production line.

| low temperature hydration(20~30℃) | W=(0.5~1)G |

| medium temperature hydration(60~65℃) | W=(2~3)G |

| high temperature hydration(85~95℃) | W=(3~3.5)G |

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.