Overview

Since FFA would produce an irritating odor and accelerate the hydrolysis rancidity rate of neutral oil, deacidification is necessary and it has long been used as the greatest economic benefit for the crude oil refining process.

Features

Alkali refining for removing acid is the most critical step in the entire refining process, and it creates conditions for decolorizing, deodorizing, hydrogenating, and deep processing of oil. After alkali refining, oil quality is improved, oil stability is increased and its storage time is prolonged.

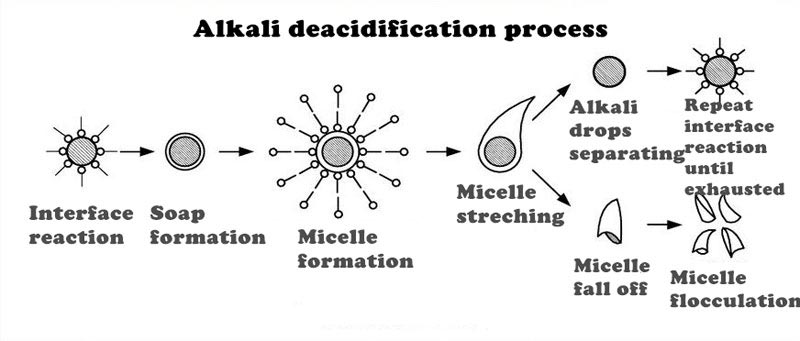

The Alkali refining method uses alkali to neutralize FFA in the oil to generate soap and the generated soap can adsorb impurities. Soap and impurities are then subsided and separated from the oil by gravitational sedimentation separation method or by centrifuge.

Alkali refining is divided into the intermittent type and continuous type, and the intermittent type is suitable for concentrated alkali refining at low temperatures with steps like pre-treatment-lye neutralization-separation of soap stock-washing separation-dehydration(dissolution)-filtration-soap stock processing-packing.

Disc centrifuge is mainly made up of the fuselage, drum, transmission, and water distribution devices. The mixture enters the drum from the bottom or top, then enters the discs from the dispensing holes in the lower and middle discs, and slides towards the inner wall of the drum, after that, the mixture is diluted by the flushing water coming from the lower dispenser. Along the inner wall of the drum up into a centripetal pump in the pump area, under the action of the centripetal pump, the heavy material is discharged to the heaviest phase outlet, while the light material is discharged from the light phase outlet.

Filtering crude oil impurities to make it less than 0.2%.After mixing with acid, the acid value of the oil is measured by sampling.

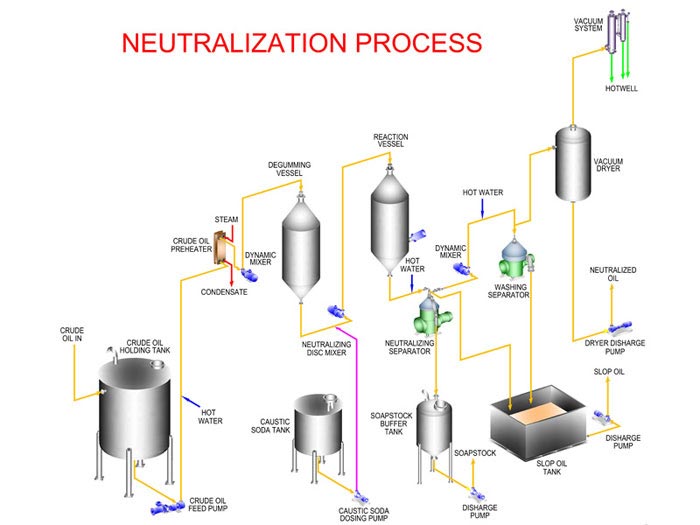

The neutralization reaction takes place in the reaction vessel. Its working principle is: the crude oil is pumped firstly from the oil holding tank to the heater for warming up to 20~40℃, then the heated, degummed oil is pumped to the mixer and mixed with phosphoric acid or citric acid for changing non-hydrated phospholipid into hydrated phospholipid in oil. After that, the oil is sent to the reaction vessel and reacts with 16~24Be'lye(around 0.05%~0.2%of the oil weight)within 5~10 minutes and the mixing speed is 60~70 r/min.After 20~50 minutes, when the oil and flocculent soap are significantly separated, reduce the stirring speed to 30 r/min and heat the oil by steam at the speed of 1C/min to accelerate soap flocculating.

After neutralization, the settling soap would be discharged by pipe to the soap stock buffer tank. When the soap stock contains more oil, stop discharging the soap stock and pump it into the soap stock tank for refining. After refining, the remaining oil from the soap can be reused in the next process.

The deacidified oil still contains a little soap and to remove the residual soap, process water would be pumped into the oil with a water temperature 3~5℃ higher than the oil. Each time the added water amount is 10%~15%of the oil volume and the washing process can be operated 1~3 times, then stirring well and keeping still for half an hour to one hour. Then,re-mixed oil and water are conveyed into the separator, and the wastewater with soap impurities is separated and discharged to the slop oil tank.

The washed oil still contains moisture and the moisture will affect oil stability, so the oil would be sent to the vacuum drier to remove moisture, and then the dehydrated water can be conveyed for further processes like decoloring, deodorizing,etc.

Finally, filtrate the dehydrated oil again to remove the residual impurities and package the oil in sealed barrels for low-temperature, drying preservation.

| Oil grade or type | Acid value/mg·KOH/g |

| Edible fried oil, sesame oil, secondary rapeseed oil | ≤5.0 |

| Edible flaxseed oil, most secondary edible vegetable oil | ≤4.0 |

| Sesame oil | ≤3.0 |

| Secondary edible lard | ≤1.5 |

| First-grade vegetable oil and lard, shortening, margarine, edible hydrogenated oil | ≤1.0 |

| Edible vegetable oil | ≤0.6 |

| Senior cooking oil, the U. S. soybean oil, Japan reconcile oil | ≤0.5 |

| Salad oil, Japanese refined lard, the U. S. soybean salad oil | ≤0.3 |

| Japanese refined vegetable oil, refined reconcile oil | ≤0.2 |

| Japanese edible plant salad oil, reconcile salad oil | ≤0.15 |

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.