Overview

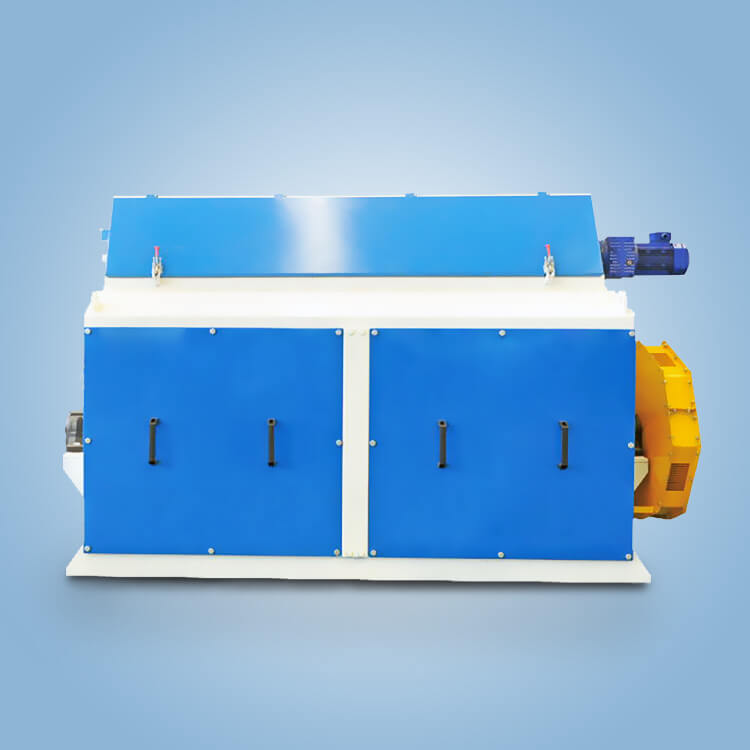

An Oilseeds sheller machine is often used with kernel shell separator and peeling machine in the pretreatment process of edible oil production line. Oilseed shelling is an important process before oil pressing. Many oilseeds contain shells and peels which have very low oil content and if not removed, the shells and peels will absorb oil and reduce oil yield.

Features

Shelling can improve oil yield, improve the quality of crude oil and oil cake, increase the handling capacity of oil pressing machines, reduce the abrasion of equipment, and is favorable for the flaking process and the comprehensive utilization of shell and peel. We provide peanut shelling machines, palm nut cracker machines, sunflower dehulling machines, and walnut cracking machines for the shelling process in the edible oil production line.

Peanut shelling machine is specially used for removing the shells of peanuts. The machine integrates peanut shelling and kernel shell separating functions. It adopts a rasp plate for shelling the peanut. After air separation of shells and kernels and gravity separation of kernels and unshelled peanuts, the kernels enter into the sack automatically. The unshelled peanuts flow into the elevator for reselling and reseparating.

Palm nut cracker machine is used for cracking palm nuts and after cracking, palm kernel shell separator is used to separate the kernels and shells by upward airflow. There are small palm nut cracker machines and large palm nut cracker machines. The cracking rate is higher than 95% and the broken rate is lower than 1%. We provide a palm nut grading machine for you to grade the palm nuts before cracking.

Sunflower dehulling machine can complete sunflower seeds cleaning, dehulling, hull removal, separating, and reseparating process in one operation. Adopt a wind-back feeding system to make the un-dehulled seeds automatically return to the dehullers for dehulling again, greatly improving the dehulling efficiency. It is excellent equipment in the world used in sunflower seed processing.

Walnut cracking machine is mainly used for cracking the walnut. It can crack walnuts of different sizes and varieties. By adjusting the internal clearance, the best shelling effect can be achieved. After cracking, a walnut kernel shell separator is used to separate the kernels and shells by upward airflow. We have a walnut grading machine available for grading walnuts before cracking.

| Model | ALC-400 | ALC-800 | ALC-1500 | ALC-1600 | ALC-3000 | ALC-3300 |

| Capacity(kg/hr) | 400 | 800 | 1500 | 1600 | 3000 | 3300 |

| Power(kW) | 2.2 | 4 | 5.5 | 7.5 | 11 | 11-15 |

| Shelling rate | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Kernel Broken rate | ≤5% | ≤5% | ≤5% | ≤5% | ≤5% | ≤5% |

| Loss rate | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% |

| Cleaning rate | ≥95.5% | ≥95.5% | ≥95.5% | ≥95.5% | ≥95.5% | ≥95.5% |

| Weight(kg) | 137 | 385 | 775 | 760 | 960 | 1315 |

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.