Overview

Generally speaking, the percentage of impurities in oil seed is 1%-6%, and the highest is 10%. so oilseed cleaner is an important machine for the oilseed pretreatment process.

Features

The screening separation mainly makes use of the different sizes between oilseeds and impurities. With the aid of the relative motion of the mixed oil seed and the sieve surface, impurities of bigger or smaller size than oilseeds are sieved out. Oilseeds screening equipment for edible oil plants mainly includes slide sieves, vibrating screens, rotary flat sieves, and rotary screens. The vibrating screen is also called a flat screen, its screen surface can do the reciprocating movement. It can be used to clean up impurities in all kinds of oilseed. Featured with high cleaning efficiency and stable performance, the vibrating screen is widely used in the cooking oil mill plant.

Winnowing refers to a cleaning method for separating impurities in oilseeds by the wind. The main function of winnowing is to remove dust and light impurities. Sometimes it can also remove heavy impurities such as metal and stone. Winnowing can also be used for separating shell or peel from kernels. The winnowing machine is based on the principle of clean oilseeds.

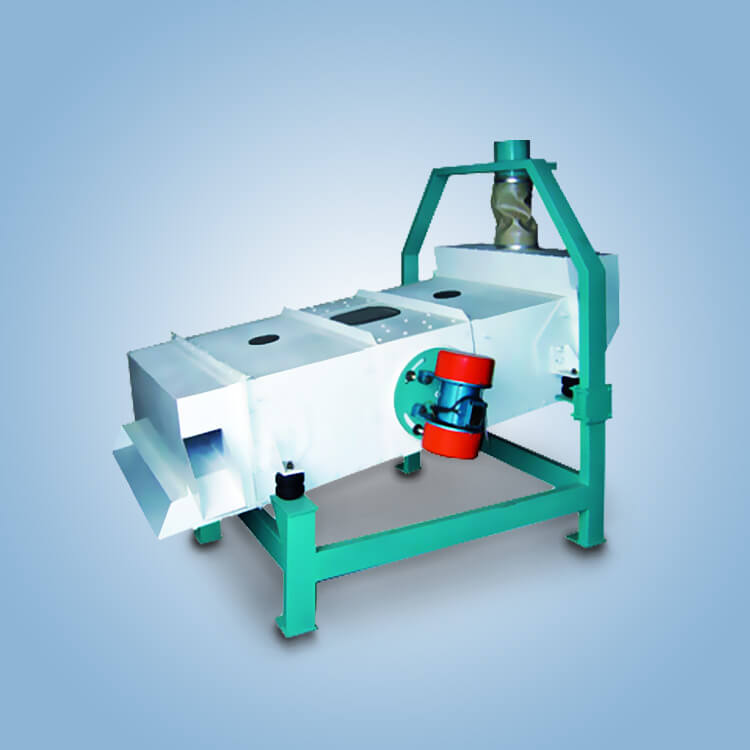

Common winnowing machines are wind separators and air-suction flat screens. 1. The wind separator is specially designed for removing heavy impurities and light impurities in cotton seeds. The structure is simple. A wind separator is often installed on the conveyor auger. It is widely used in the cottonseed oil processing plant and has an excellent cleaning effect. 2. Air-suction flat screen is a combination of the screening separation and winnowing separation. In addition to using the flat screen to sieve out impurities, the air-suction flat screen can also use wind to remove light impurities and partially heavy impurities, like dust, hull, leaf debris, lint, etc.

Magnetic separator is specially designed to remove magnetic metal impurities in oilseed. A permanent magnet or electromagnet is installed in the previous process of shelling machine, crusher, and flaking machine. Magnetic separation equipment includes magnetic steel, permanent magnetic cylinder, permanent magnetic roller, electromagnetic roller, and so on.

The specific-gravity destoner is applied to separate oil seeds and stone by the difference of density and suspension speed between them. 1. Suction-type specific gravity destoner It is composed of a feeding mechanism, sieve body, vibration mechanism, suction mechanism, and frame. 2. Blower-type specific gravity destoner Blower-type destoner has the same working principle as suction-type destoner. The main difference between suction-type and blower-type is that there is a fan at the bottom of the blower-type destoner and don't need to match a fan or wind net. But the blowing type will form positive pressure in the machine chamber, resulting in the leakage of dust air, which is not good for the working environment.

Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.