Sunflower seed oil is a vegetable oil extracted from the kernels of sunflower seeds. It contains more than 90% unsaturated fatty acids and has a higher vitamin E content than most other vegetable oils. Consuming sunflower seed oil is highly beneficial for human health, making it widely popular among consumers. The sunflower seed oil produced using the extraction process is also called "extracted oil." This method involves soaking oil-bearing materials in organic solvents and extracting the oil at high temperatures.

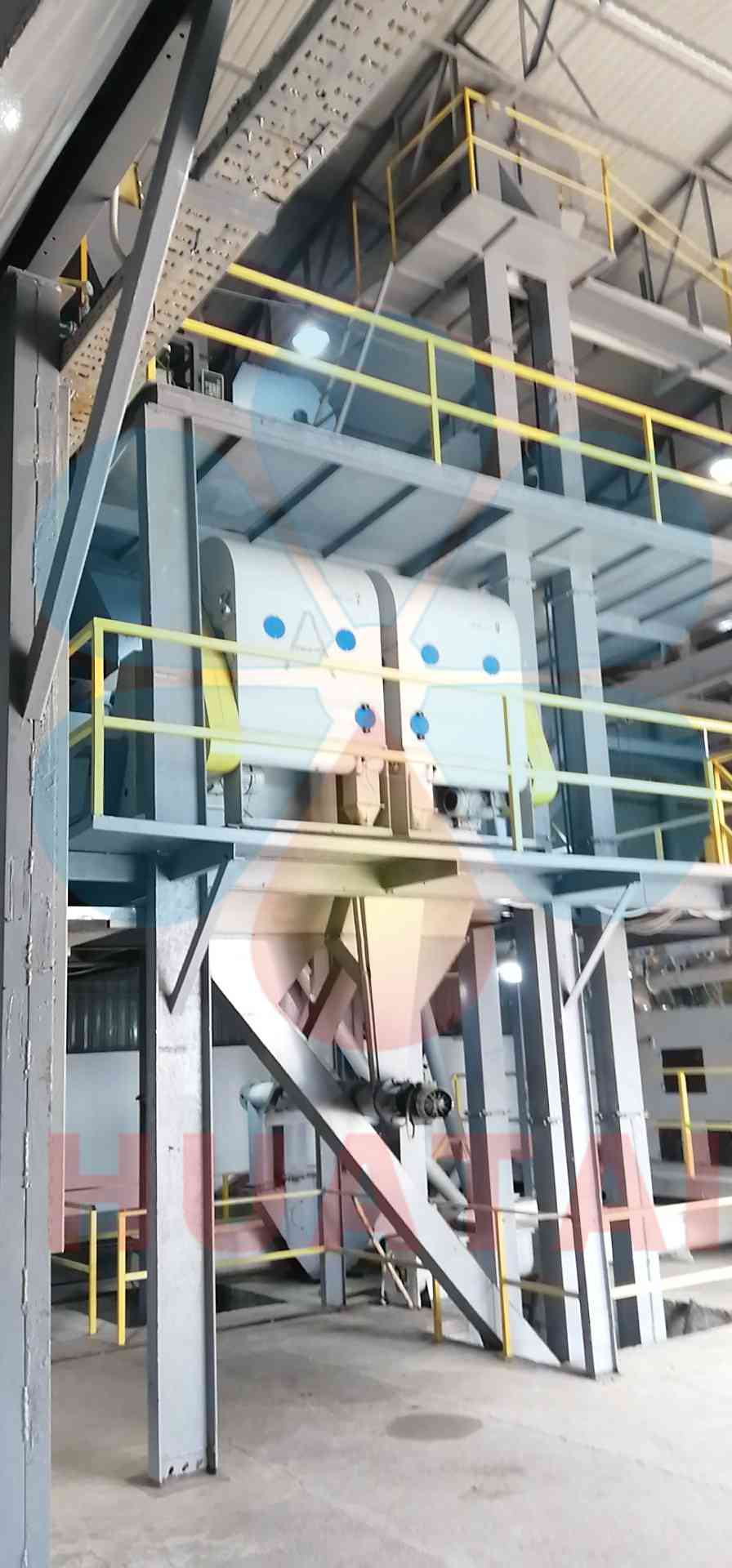

Oil Extraction: After pretreatment, the oil material (seed flakes or pre-pressed cakes) is transported to the extractor. Concentrated miscella (a mixture of oil and solvent) and wet meal are obtained through solvent extraction.

Wet Meal Desolventizing and Drying: The meal discharged from the extractor contains 25%-35% solvent. Heating is used to recover the solvent and obtain high-quality meal.

Miscella Evaporation and Steam Stripping: Evaporation uses heat to vaporize part of the solvent in the miscella, increasing the solute concentration. Steam stripping is based on the principle that miscella and water are immiscible. High-pressure direct steam is introduced into concentrated miscella, while indirect steam heats the equipment to prevent condensation of direct steam, thereby reducing the solvent content in the oil.

Solvent Vapor Condensation and Recovery: Condensation is a process in which gas releases heat and turns into liquid at the required temperature. Cooling refers to reducing the temperature of hot fluids without causing phase changes. Solvent vapor condensation and recovery minimize solvent losses in the extraction process.

The initial extracted "oil" is a mixture of organic solvents and oils, which is not edible. It must undergo a series of refining processes (such as degumming, deacidification, dehydration, decolorization, deodorization, and dewaxing) before it becomes suitable for consumption.

Degumming: Oil-soluble impurities affect the stability of the oil and the effectiveness of refining and deep processing. During alkaline refining, these impurities promote emulsification, increase operational difficulties, consumption, and reduce the quality of soapstock. During decolorization, they increase adsorbent consumption and reduce decolorization efficiency.

Deacidification: Vegetable oils contain a certain amount of free fatty acids, the quantity of which depends on the quality of the oil material. Factors like seed immaturity and high seed breakage lead to higher acid values. Particularly in high-moisture conditions, the oil quality deteriorates due to increased free acid content.Decolorization: The pigments in vegetable oils are complex and include chlorophyll, carotenoids, flavonoids, anthocyanins, and degradation products from sugars and proteins. Adsorptive decolorization is the commonly used method. Adsorptive decolorization utilizes the strong adsorption properties of adsorbents to remove pigments and impurities from heated oils.

Deodorization: Various vegetable oils have their unique flavors and tastes. Even after deacidification and decolorization, traces of aldehydes, ketones, hydrocarbons, low molecular fats, glycerol derivatives, and residual solvent odors persist in oils. Deodorization removes undesirable odors.Dewaxing: Dewaxing is an essential step in improving the quality of edible oils. Wax affects the palatability of oil, so dewaxing enhances sensory properties such as transparency and brightness. Although there are many dewaxing methods, including cold crystallization, surfactant, cold polymerization, electrostatic, and neutral winterization, industrial production mainly adopts the cold crystallization method. Due to differences in crystal properties between oil types, variations in crystallization rates, temperatures, durations, and filtration methods are required.

Advantages: High oil yield, low cost, and economic benefits. This method is widely used in the modern oil industry.

Disadvantages: Some nutrients are lost, and trace amounts of organic solvents may remain (within standards).

Extraction equipment may vary depending on the type of oil being processed. However, users are more concerned with practical production performance. Reliable and stable production is the hallmark of good equipment. For high-quality and highly efficient extraction equipment, choose Huatai Oil Machinery.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.