The palm oil content in a packet of instant noodles is about 16%-18%, with 11% of it being palm oil. Although you may not know where palm oil comes from or its specific functions, it is almost indispensable in products you use daily, such as shampoo, toothpaste, face cream, and soap, as well as lubricants in vehicles, and in foods like fried chicken, chocolate, and various snacks. Nearly half of the products on supermarket shelves contain palm oil. The global per capita consumption is 8 kilograms annually, with about 70% being used in food. However, on ingredient lists, palm oil is often labeled as sodium lauryl sulfate, palmitic acid, or simply vegetable oil, making it nearly "invisible" on labels.

Currently, palm oil is the most produced, consumed, and traded vegetable oil in the world. Extracted from the fruit of the oil palm tree, it is known as the "king of oils" due to the tree's high oil yield. The oil palm tree, a tropical tree native to West Africa, requires abundant rainfall, sufficient sunlight, and a humid environment, thriving best near the equator.

Palm fruit → Sterilization → Fruit separation → Crushing → Pressing → Filtration → Crude palm oil

Palm fruits have an oil content of about 50%, making oil extraction easy, and the residual oil rate in the palm fiber residue is very low. Therefore, using palm oil pressing equipment can achieve ideal results. It is important to note that due to the unique nature of palm fruits, common oil presses cannot extract oil from them. Specialized palm fruit oil presses are required. Henan Huatai Machinery supplies two types of specialized palm fruit oil presses globally: single-screw and double-screw palm fruit oil presses.

Crude palm oil → Degumming and deacidification → Neutralization and degumming → Adsorption and decolorization → Neutralization and deodorization → Refined palm oil

According to relevant standards, palm oil for consumption must be refined. Unrefined palm oil contains a large amount of free fatty acids, colloids, pigments, and other impurities, which can cause discoloration and significant smoke when heated, harming the health of both the cook and the consumer. Refining equipment removes harmful substances while retaining nutrients like vitamins A and E, improving the quality of palm oil. Additionally, the melting points required for industrial, food, and catering uses of palm oil vary, and refining is an effective way to adjust the melting point.

Palm oil refining equipment involves six processes: filtration, alkali neutralization, sedimentation, water washing, decolorization, and deodorization.

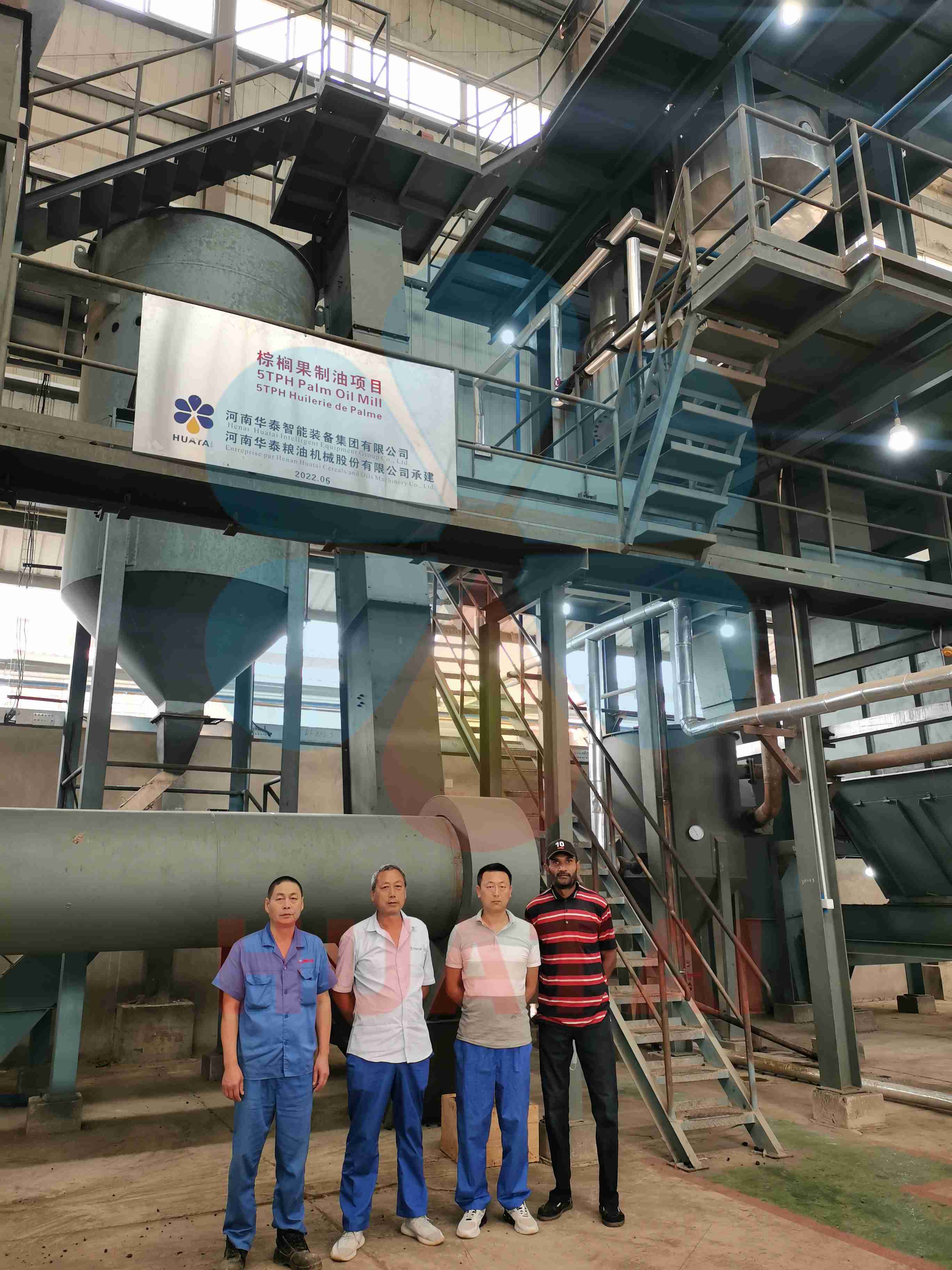

Investing in a palm oil project requires choosing the right oil machinery manufacturer. Henan Huatai Oil Machinery offers strong capabilities, reliable quality, comprehensive services, and affordable prices. We warmly welcome all customers to visit Henan Huatai to inspect and purchase edible oil production lines.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.