Investors in oil machinery equipment know that the first step in oil extraction is the pretreatment stage. The impurities in oil include mechanical impurities, colloidal impurities, lipid-soluble impurities, trace impurities, and moisture. Today, we will briefly introduce these types of impurities and the equipment needed to remove them in an oil production line.

Mechanical Impurities: These are solid impurities that are insoluble in oil. During the pressing or extraction process, crude oil is obtained, and mechanical impurities such as sand, meal powder, cake residue, fibers, and grass debris are mixed into the oil. Since they are insoluble in oil, they can be removed through simple processes like filtration and sedimentation.

• Pretreatment Equipment: Such as cleaning and de-stoning equipment, used to remove impurities and stones from the raw oil materials; crushing equipment, used to break large pieces of raw oil materials into smaller pieces suitable for processing; flaking equipment, which processes the crushed raw materials into flakes for subsequent oil pressing operations.

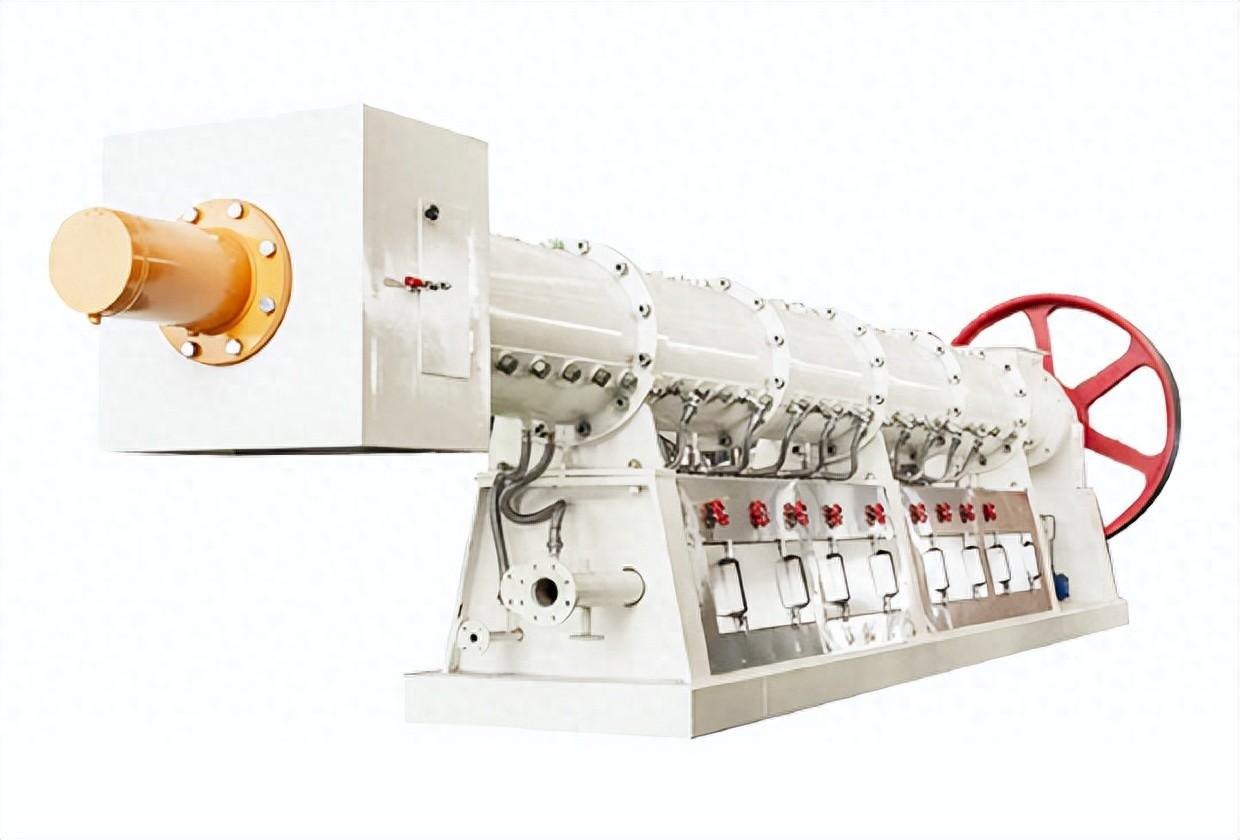

• Oil Pressing Equipment: Including oil presses and corresponding auxiliary equipment, used to extract oil from the raw materials.

• Crude Oil Filtration Equipment: Used to remove impurities and solid particles from the extracted crude oil.

• Refining Equipment: Including acid-base reaction tanks, vacuum dehydration equipment, decolorization equipment, vacuum deodorization equipment, and clay filters, used to refine crude oil into edible or industrial-grade oil. These devices can remove fibers, phospholipids, pigments, free fatty acids, moisture, waxes, and other impurities that are harmful to humans and affect oil quality.

Auxiliary Equipment: Such as steam boilers (heat transfer oil furnaces), oil pumps, and lifting equipment, which provide necessary auxiliary support for the entire production line.

Please note that specific configurations and parameters should be selected and adjusted according to actual needs and production processes. In practical applications, other auxiliary equipment and facilities may also be needed based on the specific requirements of the production line, such as edible oil dewaxing equipment, grain processing equipment, and grain drying equipment.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.