The solvents used in the oil extraction process act as industrial auxiliaries throughout the entire oil extraction process. Therefore, the composition and properties of the solvents used have varying degrees of impact on the technical indicators and product quality of the extraction production. The solubility of oil in the solvent, the separation of solvent and oil, the separation of solvent and oilseed, the separation of solvent and water, the safety of the extraction production, and the solubility of fat-soluble substances in the solvent are all closely related to the composition of the solvent. Therefore, the requirements for solvents used in oil extraction mainly include two aspects: obtaining the highest oil yield during extraction and obtaining high-quality oil and meal after extraction. Additionally, it is essential to minimize the solvent's harmful effects on the human body and ensure the safety of production operations. The ideal solvent that fully meets the extraction production requirements should have the following characteristics:

1. Good Solubility for Oils:

The selected solvent should be able to fully and quickly dissolve the oil and be miscible with the oil in any proportion. It should not dissolve or only slightly dissolve fat-soluble substances in the oilseed and should not dissolve other non-oil components in the oilseed.

2. Stable Chemical Properties:

The higher the chemical purity of the solvent, the better (except for mixed solvents). The solvent should not undergo decomposition, polymerization, or other chemical changes that alter its chemical composition and properties during storage, transportation, heating, and condensation in various extraction production processes. It should not react chemically with any components in the oilseed. Whether it is pure solvent, solvent aqueous solution, solvent gas, or a mixture of solvent vapor and water vapor, it should not corrode the equipment.

3. Easy Separation from Oil and Meal:

The solvent should be able to fully volatilize from the oil or meal at a relatively low temperature. It should have a stable and suitable boiling point, low heat capacity, low latent heat of evaporation, easy recovery, and should not be miscible with water or form azeotropic mixtures with water.

4. Good Safety Performance:

Whether it is pure solvent, solvent aqueous solution, solvent gas, or a mixture of solvent vapor and water vapor, it should be harmless to the health of operators. The oilseed after solvent removal should not have an unpleasant solvent odor or taste and should not leave harmful residues to the human body. The solvent should be non-flammable and non-explosive.

5. Environmentally Friendly:

Solvents are industrial products of modern technology, and many solvents have adverse effects on the environment or atmosphere, some of which are irreversible. Therefore, selecting solvents is a technically challenging task and a long-term research project.

6. Wide Availability:

The solvent should be readily available and inexpensive to meet the needs of large-scale industrial production.

In actual oil extraction production, the properties of the solvents used are compared with those of the ideal solvent, striving to minimize the deviation. The most commonly used solvents in oil extraction production are industrial hexane and No. 6 solvent oil.

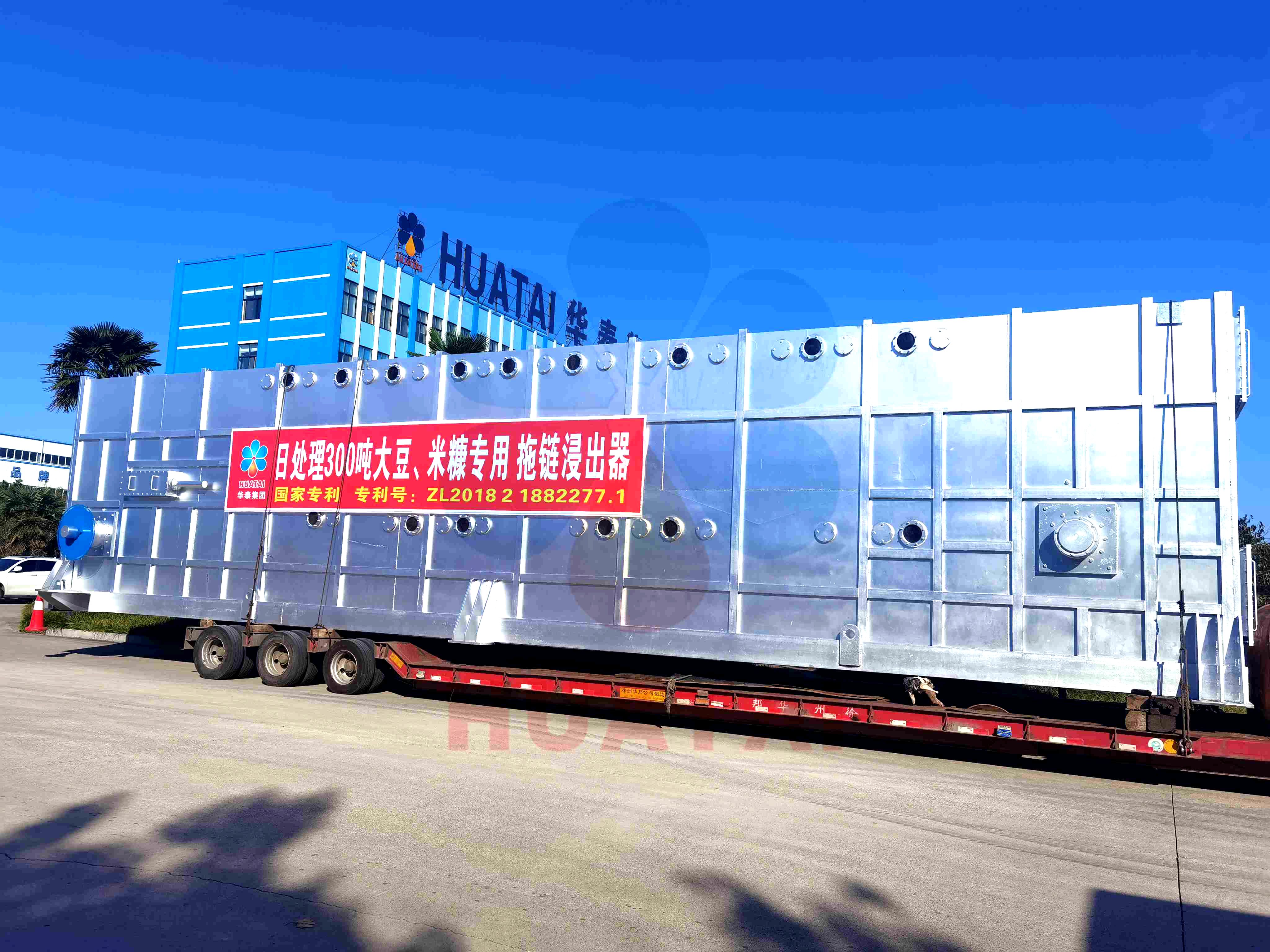

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.