Sunflower seed oil is one of the fastest-growing vegetable oils globally, ranking high in consumption and serving as a key edible oil in European countries. It is commonly extracted through two methods: pressing and solvent extraction. Pressing is a traditional physical process that uses external force to extract oil, preserving its nutritional value and flavor, making it a green and healthy choice favored by consumers. Solvent extraction, a chemical process, uses solvents to thoroughly extract oil from sunflower seeds, minimizing residual oil in the cake. It is one of the most widely used edible oil processing methods.

The solvent extraction process for sunflower seed cake mainly includes preprocessing, extraction, wet meal desolventization, mixed oil evaporation and stripping, and solvent recovery. Below is a detailed description of the process:

The sunflower seed cake is crushed, screened, and impurities are removed to adjust its particle size for the extraction process. If necessary, drying is performed to control moisture content, improving extraction efficiency.

A specific organic solvent (e.g., hexane) is used to extract oil from the sunflower seed cake. This is typically done in a closed extractor to ensure efficient solvent use and minimize volatilization. Through stirring or circulation, the solvent fully contacts the cake, dissolving the oil to form a mixed oil.

The wet meal (solvent-containing cake) undergoes desolventization, where steam or hot air evaporates the solvent. The desolventized meal can be used as feed or for other industrial purposes.

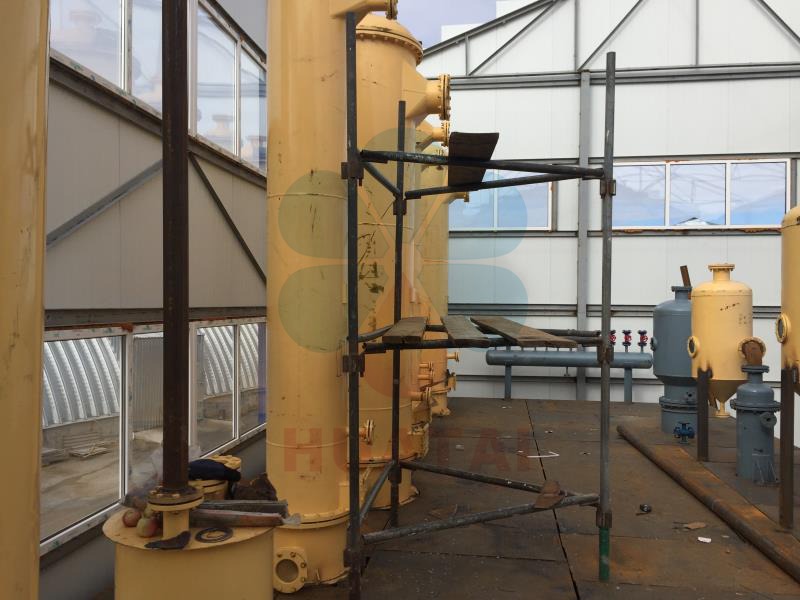

The solvent-containing mixed oil is sent to an evaporator, where heating evaporates the solvent. Further residual solvent removal in a stripping tower yields crude oil with minimal solvent content.

Solvent vapor generated during wet meal desolventization and mixed oil evaporation is condensed into liquid solvent. The recovered solvent is purified and reused in the extraction process, reducing production costs and environmental pollution.

Solvent extraction efficiently extracts oil from sunflower seed cake, achieving higher yields and reducing oil waste compared to traditional methods.

The solvent used in the process can be recycled, reducing solvent consumption and emissions, aligning with environmental standards. Optimizing processes and equipment further lowers energy consumption, promoting energy conservation.

Sunflower seed oil extracted via solvent extraction is of high quality, with a clear color and pure taste, meeting market demand for premium vegetable oil.

The project enables effective resource utilization, enhancing the added value of raw materials. By controlling production costs and expanding sales channels, it achieves strong economic returns.

Successful implementation of a sunflower seed cake solvent extraction project requires careful consideration of factors such as raw material supply, technology selection, equipment configuration, environmental requirements, and market demand. Investors should also monitor industry policies and market trends to adjust strategies promptly, ensuring long-term stable development.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.