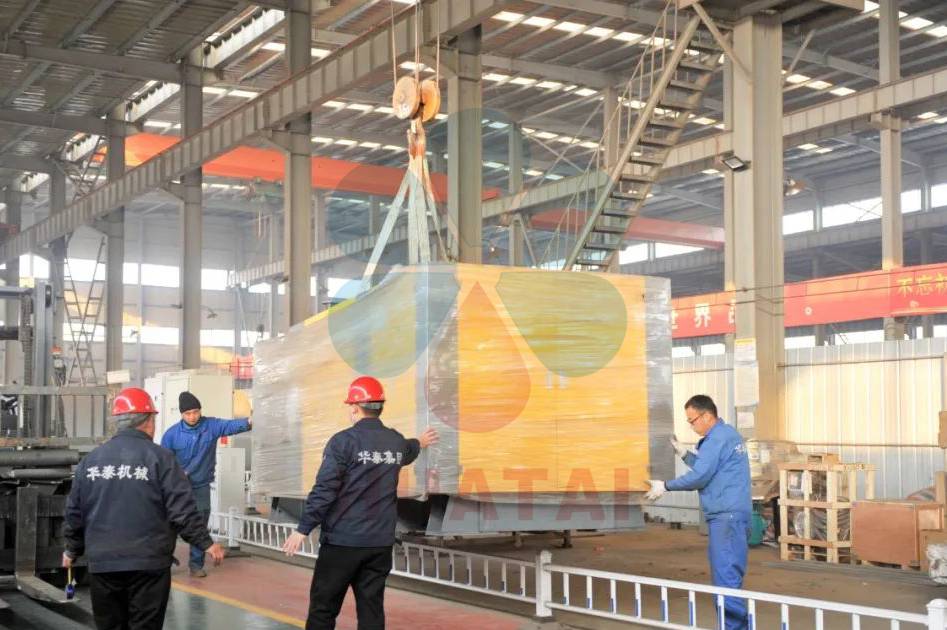

On January 5, 2024, the 300TPD soybean pretreatment, 300TPD oil extraction, and 50TPD oil refining projects contracted by Huatai Group were successively sent to Nigeria.

Soybeans are one of the important food crops in my country, mainly soybeans, which are grown throughout the country. They are a crop rich in protein. The protein content in soybeans is 35% to 40% and can be processed into various soy products.

Brewing soy sauce and extracting protein is also one of the important oil crops in my country. There are two commonly used soybean oil processing techniques: pressing and extraction. Currently, the extraction process is the most common processing technique for producing soybean oil. The oil content of soybeans is low, about 20%.

The pressing method cannot fully extract the oil in soybeans. The residual oil rate in soybean cakes is high, which reduces the oil yield and affects the quality of soybean cakes. The extraction process can fully extract soybean oil, and the residual oil rate can be controlled at about 0.5%, improving the oil yield.

The extracted soybean meal can also be used in soybean protein extraction, animal feed, and other industries. Which process is better for processing soybean oil? Which process is better for processing soybean oil needs to be decided based on the market positioning of the oil plant, the size of the oil plant, etc. Pressed soybean oil adopts a physical pressing process. During the production process, the oil is extracted through physical extrusion without additives.

Therefore, crude oil has high quality, complete color, aroma, and taste, retains various nutrients in soybeans, and has a relatively high nutritional value. However, the smoke point of pressed soybean oil is low and the oil yield of pressed soybean oil is not high, so the price is relatively high. However, the pressing process has relatively flexible equipment requirements. Different production line solutions can be configured according to the manufacturer's output, budget, site size, etc., and are suitable for small and medium-sized edible oil processing plants.

Extracted soybean oil uses a solvent to extract grease. During the extraction process, the solvent and soybean oil form a mixed oil, which needs to be recovered through high-temperature evaporation, stripping, and condensation to separate the solvent and grease. Moreover, there are still solvent residues in the crude oil, which requires refining.

The conditions are more stringent than those for pressed oil, but refined crude oil has fewer impurities, higher purity, and a higher smoke point, making it suitable for high-temperature cooking. Moreover, the oil yield of leached soybean oil is high, so the price is relatively low, and the quality of the cake after leaching is good, which can be used in industries such as animal feed or protein extraction and processing.

Because extracted soybean oil uses organic solvents to extract the oil from soybeans, its nutritional value is lower than that of pressed soybean oil. Moreover, the oil extraction equipment has a large output, high efficiency, and a high degree of automation, which can save production costs and labor costs for oil plants. Therefore, the purchase of equipment is usually a large expense, extraction is usually a process often chosen by large edible oil processing plants.

When we buy the right extraction equipment, focus on the manufacturer is very critical, the strength of the manufacturer, and the equipment is guaranteed, so that the production is more assured, and interested users can come to toHenan Huatai Cereals And Oils Machinery Co., Ltd to visit and buy.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.