Peanuts are a common food in our daily lives, known for their high nutritional value, rich in fats and proteins. They can be used as snacks, in soups, and for oil extraction, making them both affordable and delicious. However, peanuts have shells, and the edible oils we commonly see are extracted from the peanut kernels. Why can't we directly press peanuts with shells to extract oil? Is there a specific process involved?

Although peanuts have an oil content of over 40%, the ratio of peanut kernels to shells is approximately 7:3. Peanut shells themselves do not contain oil. If peanuts with shells are directly pressed, the shells will absorb some of the oil, affecting the quality of the extracted peanut oil. Therefore, to ensure the quality of peanut oil, it is necessary to remove the shells first, so that only the oil from the kernels is extracted during the pressing process.

Additionally, while peanuts with shells can be directly pressed for oil, the hard texture of the shells reduces work efficiency and causes wear and tear on the oil press. If shelling is not performed, it not only lowers the oil yield and quality but also introduces impurities like dirt and gravel from the shells into the oil, complicating equipment cleaning and making it difficult to filter the crude oil. Shelling the peanuts beforehand ensures a smoother pressing process, resulting in better oil and cake output.

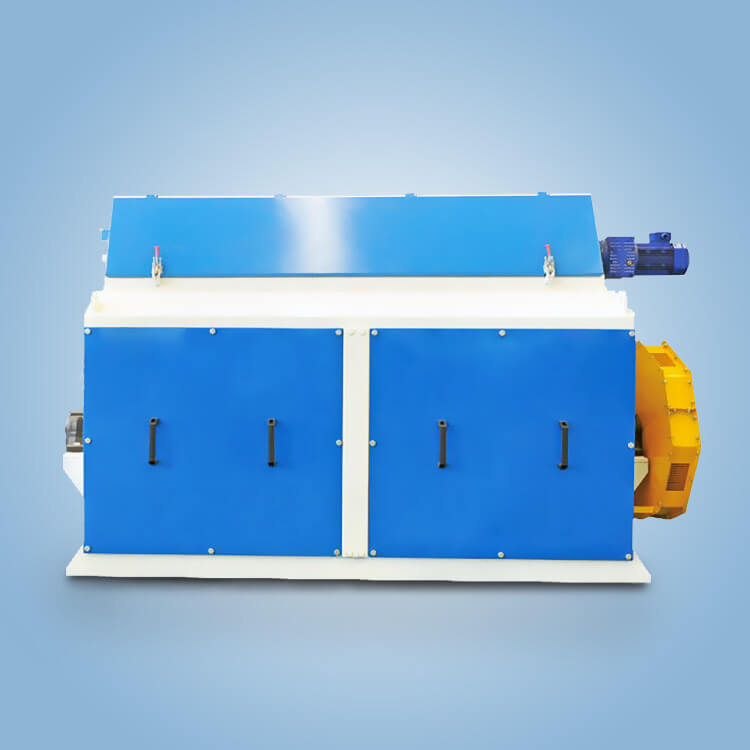

Moreover, in the production of peanut oil, the shelling process has always been a key factor limiting production efficiency. Traditional vertical centrifugal shellers, although effective, have high energy consumption and low processing capacity. To address this, Huatai Group has continuously innovated and optimized their shelling machines with scientifically sound design concepts, achieving efficient shelling of peanut kernels. The inclusion of a magnetic separator effectively prevents iron impurities from damaging subsequent equipment, significantly extending the equipment's lifespan by more than double. The main roller's new structure greatly reduces weight compared to traditional solid rollers, significantly lowering energy consumption by over 40%. Additionally, the collision rod increases the area of the curved collision plate's inner wall, enhancing the cooperation between the main roller and the collision rod, further increasing the processing capacity of peanut kernels by over 60%. More importantly, this shelling machine reduces the loss and breakage rate of peanut kernels, further improving the yield, bringing significant social and economic benefits to peanut oil production.

In summary, shelling machines are crucial for peanut oil production. They not only increase the oil yield but also improve oil quality and protect the oil extraction equipment, ensuring the progress and quality of peanut oil operations and effectively enhancing the economic benefits for enterprises.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.