The working principle of the drying tower (especially the grain drying tower) is mainly based on the principle of heating and moisture evaporation of the grain by hot air in order to realize the rapid and effective drying of the grain.

Heat source generation: the drying tower is set up with hot air furnace or heater, these devices generate high temperature hot air by burning fuel (such as coal, gas) or using energy such as electricity.

Temperature adjustment: through the control system, the temperature of the hot air furnace or heater can be precisely adjusted to meet the demand for drying temperature of different types and moisture content of grain.

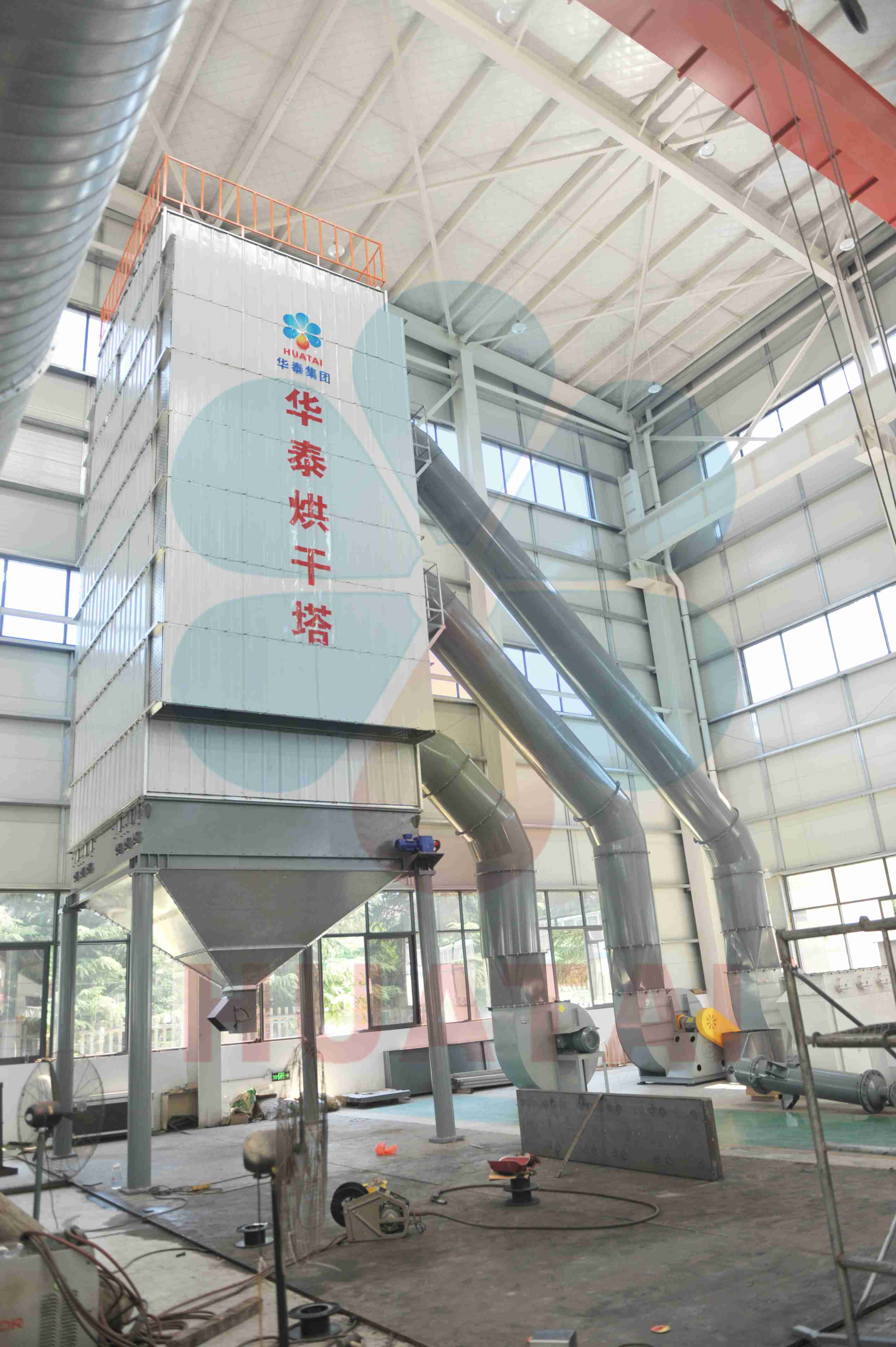

Hot air conveying: The generated high temperature hot air is sent into the drying tower through the air conveying system. The air supply system ensures that the hot air can be evenly and stably distributed in the tower, so that the grain can be evenly heated.

Grain loading: The grain to be dried is sent into the drying tower through the loading equipment.

Heat exchange: in the drying tower, the high temperature hot air and grain for full heat exchange. The hot air transfers the heat to the grain so that the moisture in the grain gradually evaporates.

Uniform heating: The grain is constantly turned or moved in the drying tower to ensure that it is heated uniformly. This helps to achieve a more efficient drying effect and avoids damage to the grain due to localized overheating.

Moisture discharge: As the water in the grain evaporates, the moisture generated is carried by the hot air and discharged out of the drying tower through the moisture discharge system. The moisture discharge system can automatically adjust the moisture discharge speed according to the humidity of the grain and the air humidity inside the drying tower to achieve the best drying effect.

Hot air circulation: part of the hot air will be recycled before it is discharged from the drying tower to improve energy utilization and reduce energy consumption.

Control system: The control system of the drying tower is responsible for monitoring and regulating the operation status of each system, including temperature, air volume, moisture discharge speed and other parameters, in order to ensure the high efficiency, stability and energy saving of the drying process.

To sum up, the drying tower uses hot air to dry grain through the steps of heating, air supply, drying and moisture removal. Its working principle is scientific and efficient, which can effectively reduce the moisture content in grain and improve the storage stability and quality of grain. At the same time, through the reasonable control system and hot air circulation technology, the drying tower can also realize energy saving and environmental protection production.

Huatai Oil Machinery provides good quality oil mill plant, time & fast delivery, perfect after-sale services, and reasonable price, contact us!

Website: https://www.huataioilmachine.com/Copyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.