Huatai relies on its technical advantages, excellent oils pressing, extracion and refining equipment, service to provide clients with oil mill plant solutions.

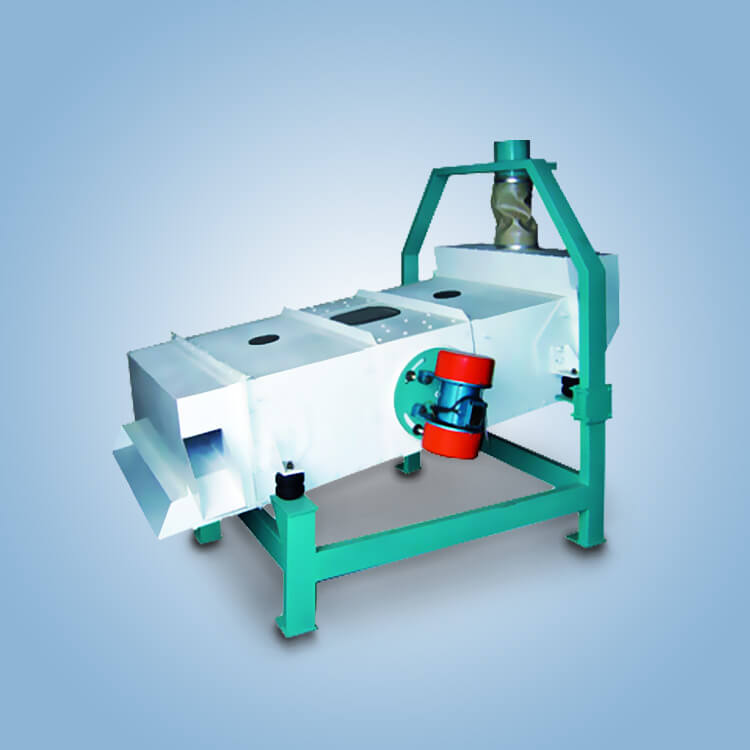

Generally speaking, the percentage of impurities in oil seed is 1%-6%, and the highest is 10%. so oilseed cleaner is an important machine for the oilseed pretreatment process.

Oilseeds crushing machine is for crushing large oilseeds like soybean, peanut, palm kernel, copra, etc., and pre-pressed oil cakes into small sizes with uniformity and few powders. The crushing process of oilseeds is vital for the improvement of flake quality and processing capacity of the flaking machine, thus oilseed crusher is the key equipment for the oil seeds preprocessing workshop.

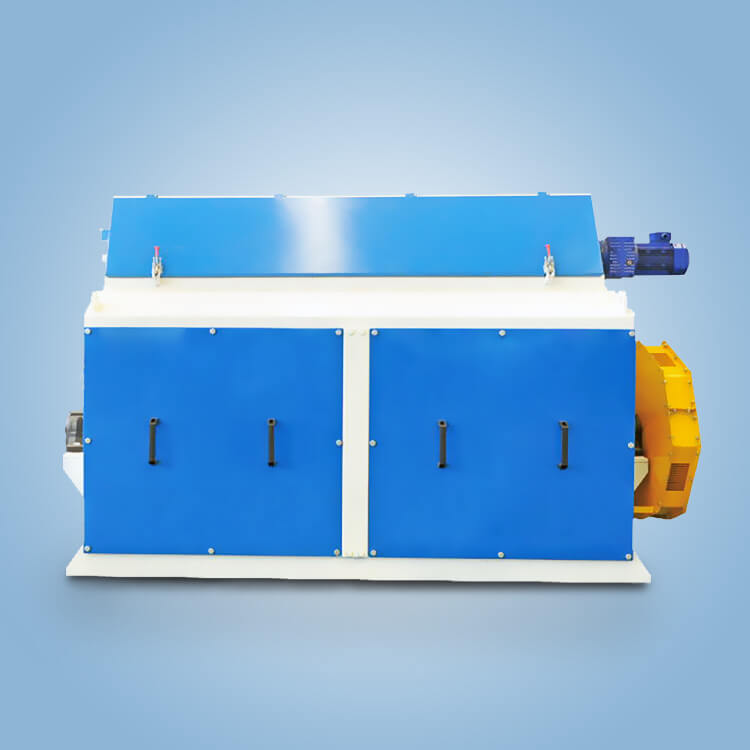

An oilseed flaking machine is vital pretreatment equipment in oil mill plants. It can turn granular oil materials into flakes by rolling the pressure of the rollers. The flaking process can help oil extraction more smoothly from oil materials.

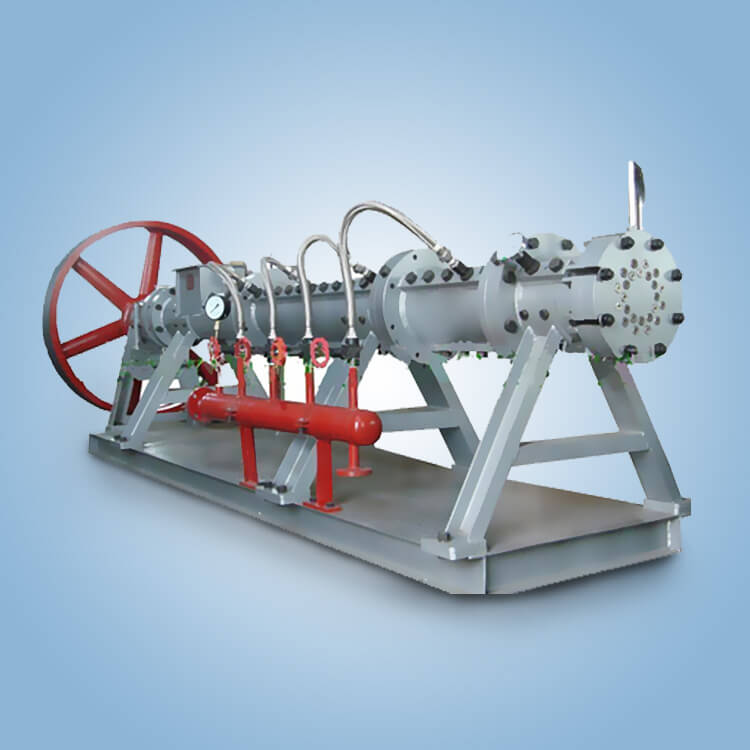

An oilseed puffing machine is for preprocessing high oil-content materials like rapeseeds, corn germ, or various pre-pressed oil cakes before sending them into an oil solvent extraction workshop. The puffing machine is suitable for soybean, rape seeds, cotton seeds, rice bran, etc. The puffing process of oil materials can improve oil yield, reduce energy consumption, and save investment in oil production equipment.

An Oilseeds sheller machine is often used with kernel shell separator and peeling machine in the pretreatment process of edible oil production line. Oilseed shelling is an important process before oil pressing. Many oilseeds contain shells and peels which have very low oil content and if not removed, the shells and peels will absorb oil and reduce oil yield.

Three points by, seven points by roasting materials. It’s key to choose a reliable oilseeds roasting machine to improve the oil yield. Temperature control oilseeds roasting machine, also named drum type oilseeds roasting machine, can roast oilseeds evenly.

Oil extractor is the main equipment in the edible oil solvent extraction process. The pretreated oilseeds or pre-pressed oil cake are sent to the edible oil extractor by the conveyor,after solvent extraction,miscella and the wet meal is obtained.Crude-extracted oil shall be refined to be edible.

Edible oil extraction equipment or tank extractor is a small-scale batch-type edible oil solvent extraction equipment. Tank extractor has both the function of extraction and meal desolventizing.It extracts oil by immersing the pre-pressed cake in solvent or miscella of various concentrations.

The solvent evaporation system adopts negative pressure evaporation technology, using the secondary steam from the desolventizer toaster as the heat source of the first evaporator and using the steam jet pump to vacuumize the system to make it works under negative pressure, having low evaporating temperature and good oil quality, saving steam and solvent consumption.

Solvent recovery systems consist of a condensing recovery system and a mineral oil system. The condensing solvent recovery equipment includes the condenser, solvent water separator, boiling tank, etc. We can equip the condenser according to your conditions.

In short, oil dewaxing adopts forced cooling to make the high melting point wax solid oil precipitate out from liquid oil and then use the method of filtration or centrifugal separation to remove them. Different oils have different wax content. It is almost necessary to dewax the following products (such as corn oil, rice bran oil, sunflower oil, cottonseed oil, etc.)

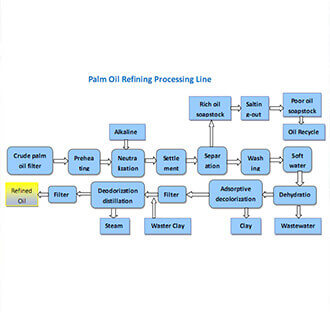

The degumming process in an oil refining plant is to remove gum impurities in crude oil by physical or chemical methods, and it is an oil purification process. After screw pressing and solvent extraction from oilseeds, crude oil mainly contains triglycerides and a few non-triglyceride.The non-triglyceride composition including phospholipids, proteins, phlegmatic, and sugar would react with triglycerides to form colloids, which are known as gum impurities.

Since FFA would produce an irritating odor and accelerate the hydrolysis rancidity rate of neutral oil, deacidification is necessary and it has long been used as the greatest economic benefit for the crude oil refining process.

The purpose of oil bleaching is not to theoretically remove all pigments but to improve the color of the oil and provide qualified materials for oil deodorization. What's more, the decolorization section can avoid oil color reversion and improve the oil product's shelf life.

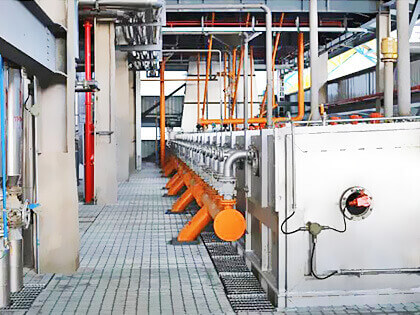

Oil Refining is the progress of removing impurities such as phospholipids, FFA, pigment, and off-flavor in cruel oil before edible application. An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment. With a high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in a large oil plant.

A refining pot, decolorizing pot, deodorizing pot, vacuum pump, steam generator, and heat conduction furnace are necessary for the edible oil refining process. They are connected with vessels by pipeline.

Rice Mill ProcessingHuatai provides customers with one-stop efficient rice milling processing technology and equipment.

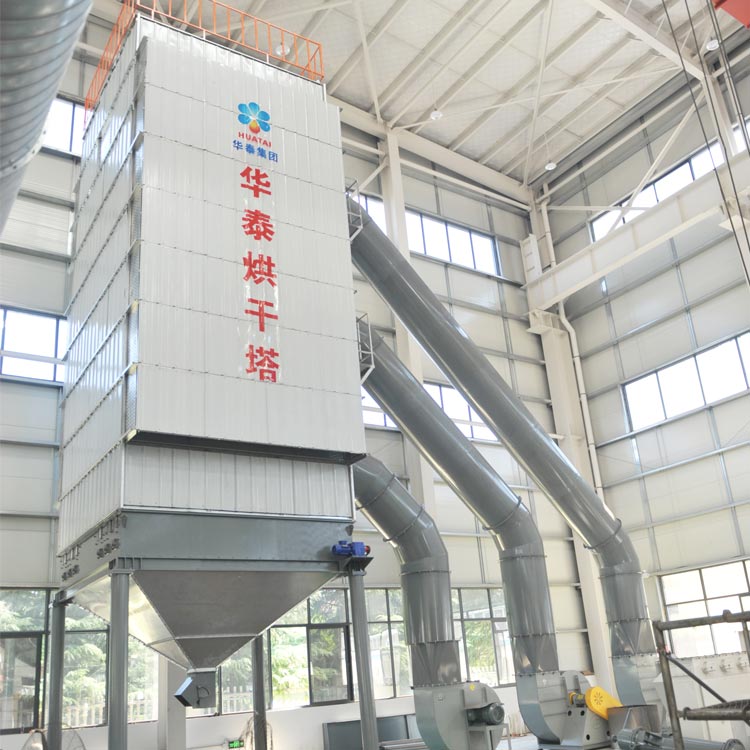

HuaTai grain drying tower is a commonly used grain drying equipment. It evaporates the moisture in the grain through the contact between hot air and grain, thereby achieving the drying effect. Its working principle mainly includes three parts: the generation, transmission and drying process of hot air.

The corn deep processing machinery adopts combined dehusking and degerming technology, and it can produce different granularity of low-fat corn grits, corn flour, and corn bran. They are also ideal foods for urban residents. Corn bran can be used for feeds.

The grains milling production line includes a grain cleaning machine, a net conveyor auger, a granary Run, an elevator, a double peeling machine , four set 30 novel milling machine and so on, one-stop production from raw materials to finished products, which can produce various specifications high mesh powder. It also can be processed buckwheat, millet, oats, beans, cowpea, beans, peas, beans, kidney beans, lentils, sorghum, black rice, and other grains.

Wheat flour mill processing equipment division stand-alone devices and equipment, can co-production special flour, flour, marking powder, 200 tons more than the specifications of flour can produce all kinds of food to meet the needs of the food industry.

The TQSF-Gravity grading stoner is mainly used for clean up, light mixed sand, soil, and high-density impurities.

The cottonseed protein dephenolization equipment is Huatai patented product, which mainly include low temperature pretreatment section, oil extraction of cottonseed oil section, cotton cake dephenolization section, etc.

Rice bran protein has essential nutrients, such as lysine. Our rice bran protein machine has won a national patent, patent No. is ZL2009 20089515.8. It can extract the protein from rice bran effectively to meet people’s dietary requirements.

Soybean protein isolated (SPI) is a full-price protein food additive, raw materials are low-temperature desolventizing soybean meal. The production of soybean protein isolated is the use of the solubility of soybean protein significantly changes the characteristics according to the different PH.

Soybean Protein Concentrate Equipment (SPC) is a soybean protein product containing more than 65% protein by high-quality soybean meal out the solubility in water or alcohol soluble nonprotein part. Production of the standard can be divided into food grade and feed grade according to customer requirements, these two kinds of standards soy protein concentrate contain the final different nutrient content.

New environmental animal oil refining,also known as new environmentally friendly animal oil refining equipment. The environmentally friendly animal oil refining equipment processing line: meat, transportation, sub-materials, cooking, oil residue separation, filtration, refining the crude oil, refining.

Animal oil equipment, also named animal oil refining equipment, in the extraction of animal offal and subcutaneous adipose tissue derived fat. Henan Huatai use of research and development of new environmentally friendly animal oil refining equipment, popular in domestic and overseas markets.

Compared with the old refining pot, our company developed a new vertical negative pressure melting pot to heat the oil (or steam) as the heat medium, adopt fully enclosed low-temperature vacuum extraction, Energy-saving environmental protection, no odor, environmental compliance. In the vacuum state of the production of low peroxide value of oil, low acid value, nice color, fragrant, large profits.

As cow breeding scale, a large number of animal fat stay by large meat slaughter and processing enterprises.In response to national environmental protection call, our latest research and developmentcomplete sets of butter oil equipment, using new technology equipment will be extracted from animal oil and made of refined lard. Huatai machinery butter equipment sold at home and abroad, Henan, Chongqing, Shandong, Anhui and more to install a number of model projects.

As pigs breeding scale, a large number of animal fat stay by large meat slaughter and processing enterprises.In response to national environmental protection call, our latest research and developmentcomplete sets of animal oil refining equipment, using new technology equipment will be extracted from animal oil and made of refined lard. Huatai machinery environmentally friendly animal oil refining equipment sold at home and abroad, Henan, Chongqing, Shandong, Anhui and more to install a number of model projects.

Animal Fats Oil Refining Equipment,the process adopts the international advanced level of "combination deacidification tower", deacidification ability, from the tower, tower packing, liquid distributor, liquid redistributor, support grid and the composition of gas and liquid imports and exports.On the basis of the traditional refining,a unique physical refining method, through the small holes on the tray tube into the oil into the steam,when deodorization, stripped of oil containing free fatty acids.

Depending on the type of oilseed, we need to use different methods of oil press: oil press is divided into pre-pressing and pressing (cold pressing, hot pressing).

Oil produced by the solvent extraction method has the advantages of low residual oil rate in the meal (high oil yield), low labor intensity, good working environment, and good meal quality.

The refining methods of vegetable oil are divided into physical, chemical, and mechanical methods.

Animal oil for human consumption generally comes from pigs, cows, chickens, fish, etc. It can be used to process food to give the food the flavor of meat.

Henan Huatai can offer the turn-key engineering & EPC

to suit your specific needs.

Huatai provides safe and intelligent oil mill plants for 60+ countries in the world.

Follow the latest developments of Henan Huatai Cereals And Oils Machinery Co., Ltd., and learn more about oil extraction.

the South American company ordered a 1,500T/D soybean pretreatment, extraction, and refining complete set of equipment from Henan Huatai Cereals and Oils Machinery Co., Ltd., a subsidiary of China's Henan Huatai Intelligent Equipment Group, and officially began to ship. In order to shorten the construction period and put the project into operation as soon as possible, the project adopts partial shipments. The equipment delivered this time is mainly concentrated

READ MORE

Sesame oil can be divided into four kinds , sesame crude oil, refined sesame seed oil, small grinding sesame oil, refined sesame oil, four kinds of oils and fats with different emphasis, and its processing technology also makes a difference:

READ MORE

HuataiNews

TechnologyNews

Generally, the safe moisture should lower 10%. If temperature of cottonseed exceed 30°C, some measure should be taken immediately. About 40% hull existing cottonseed only obtain 0.5%-1.0% oil and high waxiness, brown pigment and pesticide residue. In addition, it has about 4% short fiber, which will reduce the productive energy and oil output.

READ MORE

After the oil is processed by the refining equipment, it can reach the national standard and the moisture in the oil. Impurities, acid value and peroxide value all meet the quality standards set by the state, and it is not easy to be rancid and deteriorated, but easy to store, the color is crystal clear, the taste is light, the cooking does not produce a lot of fumes, the flavor is good, the taste is good.

READ MORE

With over 38 years of experience at Henan Huatai, we will ensure you receive the best guidance.

Get a QuoteCopyright @ Henan Huatai Cereals And Oils Machinery Co.,Ltd.